Lois Ndiba of Food Safety International leads the training (Image By Amadi Kwaa Atsiaya)

On Monday the 29th and Tuesday the 30th of May, 2023, Superfine Africa Nuts Limited conducted HACCP training for its members of staff. This is the second training taking place at Superfine Africa Nuts Limited within the month. HACCP is one of the many food handlers’ trainings that food processing facilities have to undertake and implement if they are committed to the production of safe products for human consumption. This was a highly interactive training where participants were divided into groups and did some practical work using the factory’s process flow.

The Hazard Analysis Critical Control Points date back to the 1960s and is closely associated with space exploration by the American agency NASA (National Aeronautics and Space Administration). As they plotted the adventure that was to take them nearly half a million kilometers away from the Earth, they thought about every manner of issue that could go wrong on the trip. If the crew fed on something which could cause illness, then that would be a big disaster; let alone the possibility of a major breakdown or system malfunction in the spacecraft. That is how they came up with guidelines that came to inform what we know now as the Hazard Analysis Critical Control Points.

Yvonne Obuyekha, Shelmith Ngare, Purity Wanjira, and Naomi Macharia doing an assignment during the training (Image By Amadi Kwaa Atsiaya).

Hazard Analysis Critical Control Point, or HACCP, is a management system that focuses on analyzing and reducing biological, chemical, and physical risks throughout the production, handling, and distribution of raw materials as well as during the manufacture, distribution, and consumption of finished goods. HACCP aims to forecast and minimize potential threats to food safety. This begins with putting together the HACCP team, which ideally should be a composite of the facility’s staff and management.

Naomi Macharia all attention during the training (Image By Amadi Kwaa Atsiaya)

HACCP rests on seven principles. The first principle is to do with conducting a hazard analysis; listing the steps in the process and identifying the places where major dangers are likely to arise. The focus by the HACCP team will be on risks that the HACCP plan can prevent, eliminate, or control.

Principle number two seeks to determine Critical Control Points (CCPs). A critical control point (CCP) is a point, step, or method when control can be applied to prevent, eliminate, or reduce risk to acceptable levels for food safety. A critical control point (CCP) may be able to address more than one risk to food safety, or multiple CCPs may be required to address a single risk. The amount of CCPs required depends on the steps in the processing and the level of control required to ensure food safety.

The trainer looks at a group’s assignment (Image By Amadi Kwaa Atsiaya)

Principle number three sets critical limits. In order to prevent, eliminate, or significantly reduce the likelihood of a food safety hazard, a biological, chemical, or physical parameter must be managed at a critical control point (CCP) to a critical limit (CL). The critical limit is typically an indicator, such as a measurement of time, temperature, water activity, pH, weight, or some other indicator based on scientific research and/or legal requirements.

The fourth principle establishes monitoring procedures. At each critical control point, the HACCP team will outline monitoring protocols for the measurement of the critical limit for the hazard in question. Monitoring protocols are supposed to specify how the measurement will be taken, when it will be taken, who will be in charge of it, and how frequently it will be taken throughout production.

Up close with the trainer (Image By Amadi Kwaa Atsiaya)

The fifth principle aims to set up modalities for remedial action in case a hazard will be noticed. The HACCP group will recognize the steps that will be taken to anticipate possibly dangerous elements in the production chain and the steps that are required to rectify the method. This as a rule incorporates distinguishing proof of the issues and the steps taken to guarantee that the issue will not recur. Principle number six builds up confirmation methods. This could include exercises such as inspecting of CCPs, record surveys, earlier shipment surveys, instrument calibration, and item testing as a part of the confirmation exercises.

Guideline number seven is to do with record-keeping and documentation. A key component of the HACCP plan is recording data that can be utilized to prove that the foodstuff was not only prepared but delivered securely. Here, the expectation is that the records shall incorporate data on the HACCP Group, item depiction, risk examination, the CCPs recognized, basic limits, observation framework, remedial action, recordkeeping methods, and confirmation methods.

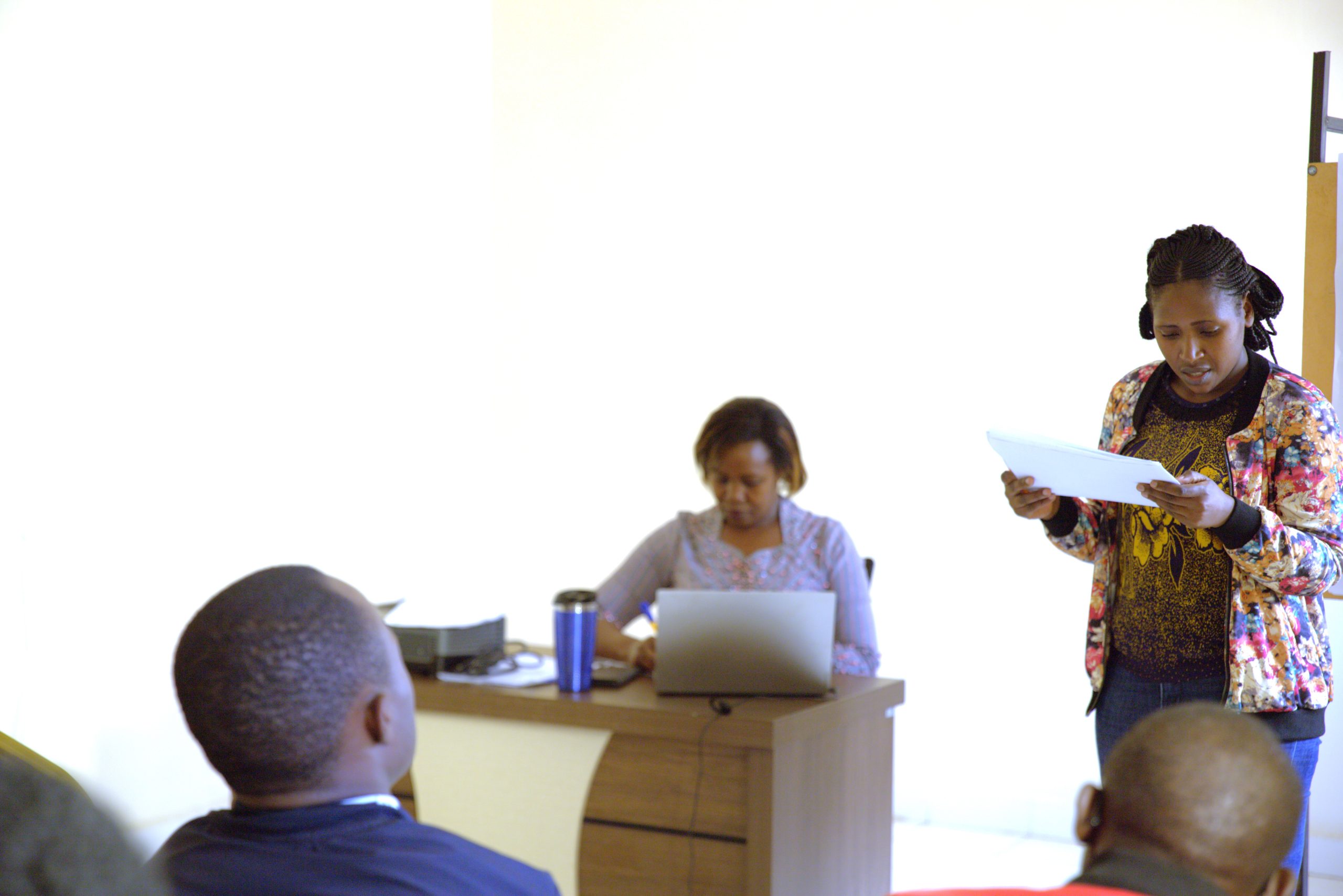

Mwikali Mumo makes a presentation during the training (Image By Amadi Kwaa Atsiaya).

The HACCP principles go hand in hand with another important tool for hazard analysis, known as the Ishikawa Fishbone. This tool was developed in the 1960s by Kaoru Ishikawa, a Japanese who worked in the shipbuilding industry. Ishikawa came up with a schema that could help the industry to determine the possible sources of flaws in the process. Thus came forth the diagram known as the Ishikawa fishbone, which has five ‘bones’ to the trunk. These are Man, Machine, Method, Material, and Milieu. In the food industry, the Ishikawa Fishbone was adopted as a tool to help examine and note the various elements that could possibly introduce a hazard to the product.

Nelson Kinyua, Wanjiku Ng’ang’a and Mercy Ndanu in a group discussion during the training (Image by Amadi Kwaa Atsiaya).

Man could be the source of hazards through handling, bodily contact, and other activities that bring humans in contact with the product. Machines, even though they are useful in making work easier, could as well be the conduit through which a hazard is introduced into the product. The culprit could as well be the method that is applied in a process; just as the material being used in production. Apart from all the aforementioned, a hazard could as well emanate from the environment (milieu). At all stages of production, the HACCP team is supposed to critically examine and establish the possible hazards from the five possible hazard sources, and come up with ways to eliminate, reduce or mitigate the effects of such hazards.

Joseph Ngure, Margaret Njoki, Miriam Mbura and Mwikali Mumo during the training (Image by Amadi Kwaa Atsiaya).

Using these tools, the trainees critically examined the Superfine Africa Nuts process flow, each group taking on an assigned section, and coming up with observations and informed suggestions that will go a long way in enhancing the company’s HACCP plan.

Wrtitten By Amadi Kwaa Atsiaya